Categories

New Blog

NDIR vs.Electrochemical Sensors: A Technical Comparison and Scenario Selection Guide for SO₂ Monitoring

January 15 , 2026In the field of industrial environmental monitoring, the accurate detection of sulfur dioxide (SO₂) is a critical step in safeguarding ecological security. As two mainstream technical solutions, non-dispersive infrared (NDIR) and electrochemical sensors demonstrate distinct competitive advantages in different application scenarios, based on their unique technical mechanisms.

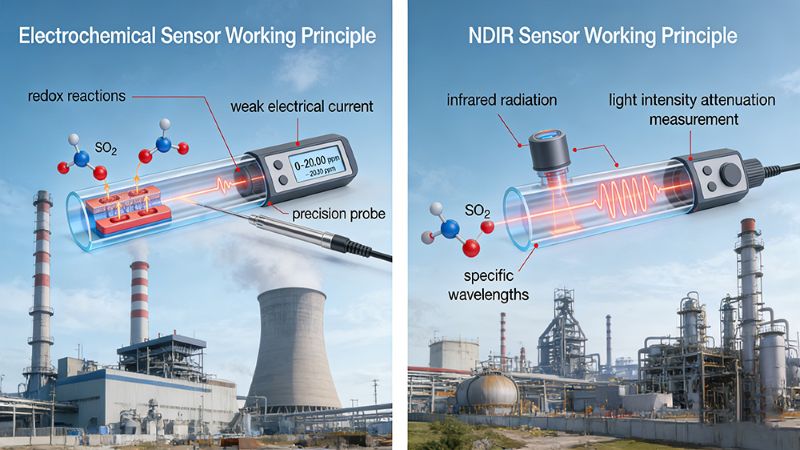

The core working principle of an electrochemical sensor lies in electrochemical reactions. When SO₂ gas molecules enter the sensor chamber, they trigger redox reactions on the electrode surface, generating a weak electrical current that is directly proportional to the gas concentration. This design endows the sensor with exceptional sensitivity, enabling it to accurately capture low-concentration SO₂ in the range of 0–20.00 ppm. It can be likened to a precision probe tailor-made for flue gas monitoring in power plants.

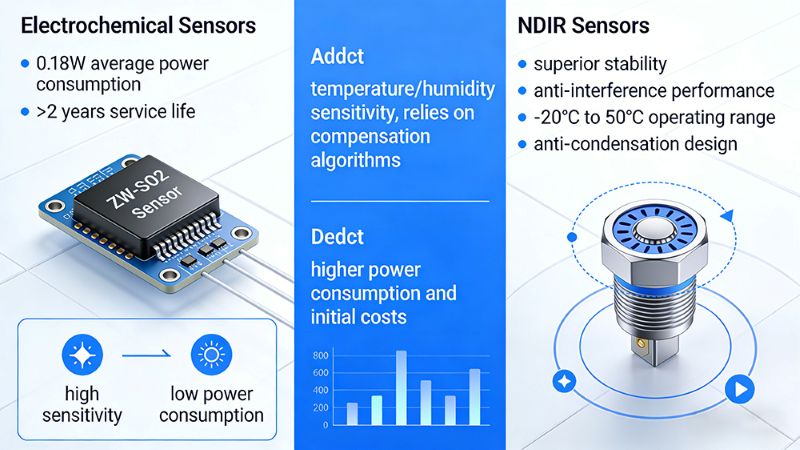

Electrochemical sensors excel in high sensitivity and low power consumption. Take the ZW-SO2 sensor as an example: with an average power consumption of only 0.18W and a service life of over 2 years, it meets the long-term continuous monitoring needs of power plants at minimal operational costs. However, this type of sensor is sensitive to temperature and humidity fluctuations, and relies on compensation algorithms to maintain detection accuracy in high-humidity environments.

NDIR sensors are characterized by superior stability and anti-interference performance. Unaffected by dust and corrosive gases, they can operate stably within an extreme temperature range of -20°C to 50°C and high-humidity conditions. Their anti-condensation design further enhances reliability in harsh working environments. That said, this stability comes with higher power consumption and initial procurement costs, making NDIR sensors more suitable for scenarios where equipment lifespan and data stability are top priorities.

For flue gas monitoring in power plants, electrochemical sensors are the optimal choice. Their ability to accurately detect low-concentration SO₂ and simultaneously output temperature and humidity data provides solid support for desulfurization efficiency evaluation and compliance reporting. Additionally, their low-power feature allows for long-term online operation without frequent maintenance.

In complex environments such as chemical industrial parks or smelting workshops, NDIR sensors gain a distinct edge. They can withstand the combined challenges of dust, corrosive gases, and extreme temperature and humidity, delivering consistent and reliable data to support ecological safety early warning systems.