Categories

New Blog

Practical Test of LoRaWAN PM2.5/PM10 Sensor: Core Adaptation to Industrial Scenarios, Stable, Durable and Low-Maintenance

January 30 , 2026The core application scenarios of PM2.5/PM10 sensors undoubtedly lie in the industrial sector. Dust-prone areas such as cement plants, flour mills, and industrial workshops have extremely high requirements for the accuracy and stability of dust monitoring. As a LoRaWAN-based sensor, the LW313D focuses on adapting to industrial scenarios. This article focuses on testing its performance in industrial scenarios while briefly explaining other auxiliary scenarios, helping industrial users quickly assess its suitability.

Industrial scenarios (factory workshops, dust monitoring areas): The LW313D is stable, durable, and enables efficient data transmission, making it adaptable to various industrial working conditions. The core of industrial dust monitoring is to accurately capture changes in dust concentration, withstand harsh environments, and realize remote data management and control—all of which are the core advantages of the LW313D.

Test results show that the LW313D is optimized specifically for industrial scenarios and is suitable for high-dust environments. It can operate stably in workshops and stockyards with a dust concentration exceeding 500μg/m³, covering a maximum monitoring range of 0-1000μg/m³. Relying on the laser scattering principle, it achieves high monitoring accuracy, capable of distinguishing subtle changes of 1μg/m³, with errors controlled within a reasonable range—fully meeting the precision requirements for industrial dust monitoring.

Industrial scenarios are often accompanied by temperature and humidity fluctuations as well as dust erosion, so the durability of the sensor is crucial. The LW313D can adapt to harsh working conditions of -20℃ to 60℃ and 0-95%RH (non-condensing), unaffected by high temperatures, high humidity, and heavy dust interference. Its body adopts a dustproof and waterproof design, which can effectively prevent industrial dust from entering the monitoring chamber, reduce the probability of failures, and achieve a service life of more than 5 years. This eliminates the need for frequent replacements and lowers the maintenance costs of industrial monitoring.

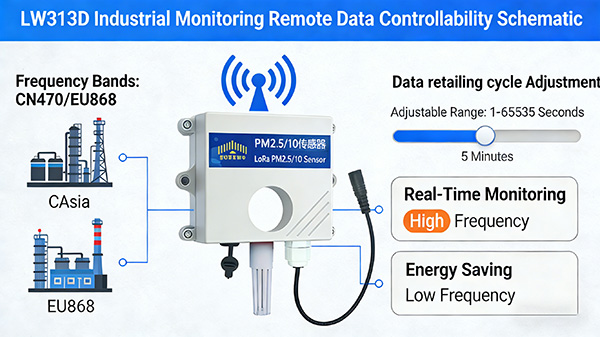

One of the core requirements of industrial monitoring is remote data controllability. The LW313D supports the LoRaWAN wireless transmission protocol and covers multiple frequency bands such as CN470 and EU868, making it suitable for industrial plants in different regions. It has a default data reporting cycle of 5 minutes, which can be flexibly adjusted between 1 and 65535 seconds. This not only meets the needs of real-time monitoring but also allows adjusting the reporting frequency according to the plant's requirements to save energy consumption.

It can remotely transmit real-time PM2.5/PM10 data to the industrial monitoring platform. Staff do not need to be on-site for duty; they can check the dust concentration at each monitoring point in real time in the central control room. At the same time, upper and lower threshold values for data can be set freely. Once the dust concentration exceeds the standard, the sensor will automatically report the data three times and trigger the plant's alarm devices to issue a reminder. This enables timely identification of potential dust accumulation hazards, avoids safety risks, and ensures production safety.

2. Adaptation to Other Auxiliary Scenarios

In addition to core industrial scenarios, the LW313D can also be used as an auxiliary tool in other scenarios. When used in indoor scenarios (offices, workshop rest areas), it operates quietly without interference and can simultaneously monitor temperature and humidity. In outdoor scenarios (around factory areas), it can realize simple dust monitoring and adapt to a wide temperature range. However, its core advantages remain focused on industrial dust monitoring.

The LW313D takes industrial scenarios as its core adaptation direction. Its characteristics of high precision, stability, durability, and remote controllability perfectly match various needs of industrial dust monitoring. Whether in high-dust workshops, stockyards, or various industrial plants, it can function stably and provide reliable monitoring support for dust prevention and control in industrial production.

If you would like to learn more, please visit our web page: https://www.zonewuiot.com/gas-sensors_c11